If you've been around the custom printing world lately, you've probably heard people buzzing about DTF transfers. And honestly? The hype is totally justified. Direct-to-Film (DTF) printing has quietly become one of the biggest game-changers in custom apparel, and it's solving problems that have frustrated businesses for years.

Whether you're running a print shop, selling custom merch online, or just curious about what all the fuss is about, DTF is worth understanding. It's not just another printing method – it's a technology that's reshaping how we think about custom apparel production.

What Exactly Are DTF Transfers?

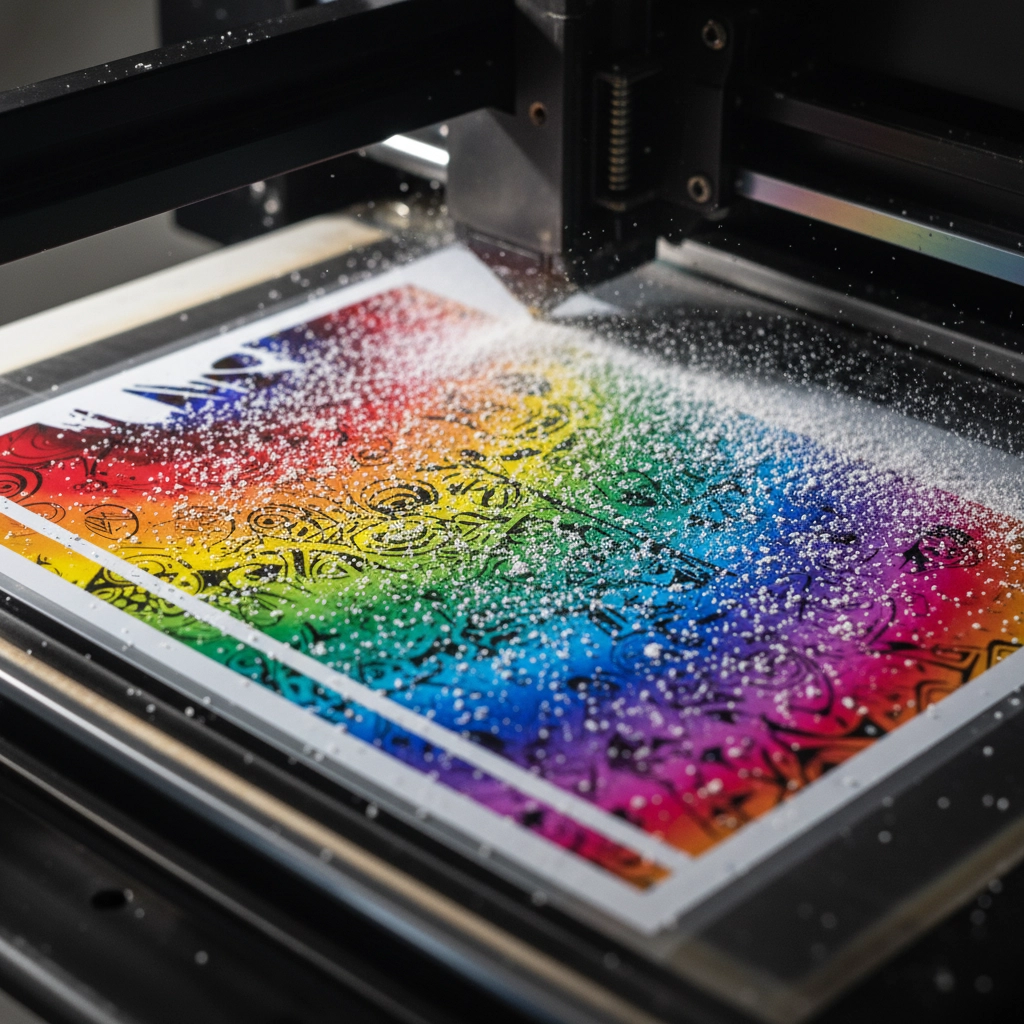

Let's start with the basics. DTF printing involves printing your design onto a special PET film using an inkjet printer, applying adhesive powder while the ink is still wet, curing the transfer with heat, and then pressing it onto fabric. Think of it as creating a custom sticker that bonds permanently with fabric under heat and pressure.

The process might sound complicated, but it's actually pretty straightforward once you get the hang of it. The key difference from other methods is that you're printing on film first, not directly on the garment. This seemingly simple change opens up a world of possibilities.

What makes DTF special is its flexibility. Unlike Direct-to-Garment (DTG) printing that requires fabric pretreatment, or screen printing that needs separate screens for each color, DTF works on virtually any fabric that can handle heat. Cotton, polyester, blends, even challenging materials like nylon and leather – DTF handles them all.

Why DTF Is Taking Off Like Crazy

Versatility That Actually Makes Sense

Here's where DTF really shines: it works on everything. Remember the frustration of turning away customers because their fabric choice wouldn't work with your printing method? DTF eliminates that problem entirely.

According to Printing Industries of America, fabric compatibility has been one of the biggest barriers to growth in custom apparel. DTF transfers work beautifully on dark fabrics, light fabrics, and all those tricky in-between colors that used to cause headaches. The prints come out vibrant and detailed, with excellent opacity that makes colors pop even on dark backgrounds.

Perfect for Small Orders (Finally!)

One of the biggest pain points in custom printing has always been small orders. Screen printing setups are expensive and time-consuming for just a few pieces. DTG can work for small runs, but the fabric limitations and pretreatment requirements make it less than ideal.

DTF changes this equation completely. You can print transfers in advance and store them, then fulfill orders on demand. Got a customer who wants 12 shirts for a family reunion? No problem. Someone needs a single custom hoodie? Easy. As we discussed in our recent post about game-changing DTF printing, this flexibility is revolutionizing how small businesses approach custom apparel.

Quality That Impresses

DTF transfers produce prints that look and feel professional. The colors are vibrant, the detail is sharp, and the finished product has a soft hand feel that customers love. Unlike some vinyl transfers that can feel thick and plasticky, properly applied DTF transfers integrate well with the fabric.

The durability is impressive too. When applied correctly, DTF transfers resist cracking, peeling, and fading through multiple wash cycles. This quality consistency has made DTF a favorite among businesses that can't afford to have quality issues affect their reputation.

The Business Benefits That Matter

Lower Risk, Higher Flexibility

One of the smartest things about DTF is that you don't have to dive in headfirst. Many businesses start by ordering pre-printed transfers from suppliers, testing the waters before investing in equipment. This low-risk approach lets you see if DTF fits your business model without a massive upfront investment.

For businesses already in the custom printing game, DTF complements existing capabilities rather than replacing them. High-volume screen printing for large orders, DTF for small batches and detailed work – it's a combination that makes financial sense.

Workflow Efficiency

DTF transforms your workflow in practical ways. You can batch print popular designs during scheduled production runs, cut them up, and stockpile them for future orders. This approach smooths out production scheduling and reduces turnaround times.

The process also scales well. Start with a basic setup for small volumes, then expand as your business grows. Equipment manufacturers like Epson and Roland DG have developed DTF-specific solutions that make scaling straightforward.

Who Should Pay Attention to DTF?

Print Shop Owners

If you run a print shop, DTF probably deserves a spot in your service lineup. It fills the gap between small custom orders that aren't profitable with screen printing and the fabric limitations of other digital methods. Many successful shops use DTF to handle those "difficult" orders while keeping their main production lines focused on high-volume work.

E-commerce Sellers

Online sellers on platforms like Etsy, Amazon, or their own websites find DTF particularly valuable. The ability to test designs without inventory risk, combined with the professional quality results, makes DTF ideal for the e-commerce environment. You can offer more variety without the storage and cash flow challenges of pre-printed inventory.

Corporate Clients and Promotional Product Companies

Companies needing branded apparel appreciate DTF's versatility and quality. Whether it's employee uniforms, promotional items, or event merchandise, DTF handles the variety of garment types and colors that corporate clients often request.

The Technology Keeps Getting Better

DTF technology continues to evolve rapidly. Equipment manufacturers are improving print speeds, reducing costs, and making the process more user-friendly. Software solutions are getting smarter, and supply chains for films and adhesives are becoming more robust and cost-effective.

The SGIA (now PRINTING United Alliance) has noted DTF as one of the fastest-growing segments in digital textile printing, with adoption accelerating particularly among small and mid-size businesses. This growth trajectory suggests DTF isn't a passing trend but a technology establishing itself as a permanent fixture in the custom apparel landscape.

Looking Forward

The conversation around DTF reflects broader changes in the custom printing industry. Customers want more options, faster turnarounds, and higher quality – all at reasonable prices. DTF delivers on these expectations in ways that traditional methods often can't.

As we explored in our analysis of printing trends in 2025, on-demand customization is becoming the standard, not the exception. DTF fits perfectly into this trend by making small-batch, high-quality printing economically viable.

Whether you're considering adding DTF capabilities to your business or just trying to understand why everyone's talking about it, the technology addresses real problems with practical solutions. It's not magic – it's just smart engineering applied to longstanding industry challenges.

The DTF conversation isn't just hype. It's businesses recognizing a tool that can expand their capabilities, serve more customers, and improve their competitive position. In an industry where flexibility and quality determine success, DTF offers both in a package that actually makes business sense.

That's why everyone's talking about DTF transfers. And why you should be too.