The apparel printing industry is experiencing a massive shift, and Direct-to-Film (DTF) technology is leading the charge. If you've been wondering whether DTF is just another printing fad or the real deal, let me tell you – it's definitely the latter. This innovative printing method is revolutionizing how we think about custom apparel, offering solutions that traditional methods like screen printing and DTG simply can't match.

What Makes DTF Printing So Special?

DTF printing works by printing your design onto a special film, then using heat to transfer that design onto fabric. Sounds simple, right? But don't let the straightforward process fool you – the results are anything but basic. According to the Specialty Graphic Imaging Association, DTF technology has seen unprecedented adoption rates among commercial printers, with over 65% of surveyed businesses planning to integrate DTF capabilities within the next two years.

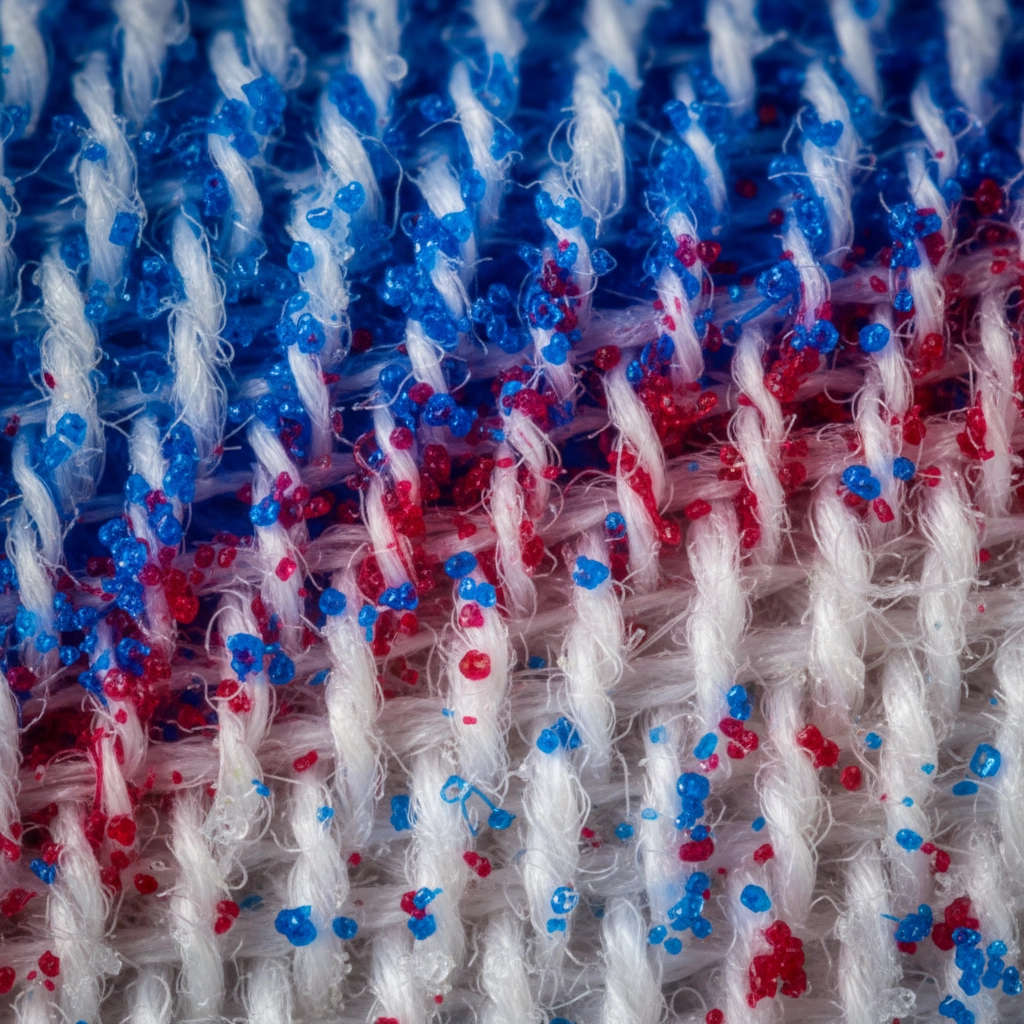

The magic happens when special DTF inks, including a crucial white ink layer, create vibrant, detailed prints that work on virtually any fabric type. Unlike DTG printing that's limited to cotton and cotton blends, DTF opens up a world of possibilities across polyester, silk, denim, and even some hard goods.

Universal Fabric Compatibility: The Game Changer

One of the biggest reasons DTF is taking over is its incredible versatility. Traditional screen printing requires different setups for different fabrics, and DTG printing only works well on cotton. DTF? It works on everything.

Whether you're printing on a cotton t-shirt, polyester athletic wear, or even leather jackets, DTF delivers consistent, high-quality results. This universal compatibility means businesses can expand their product offerings without investing in multiple printing technologies. At Abstract Printing Solutions, we've seen firsthand how this flexibility allows our clients to serve diverse markets with a single printing solution.

Superior Print Quality That Lasts

Let's talk about durability – because what good is a beautiful print if it fades after a few washes? DTF prints are incredibly durable, often outlasting traditional vinyl transfers and screen prints. The ink penetrates deep into the fabric fibers, creating a bond that resists cracking, peeling, and fading.

Industry testing by the Printing Industries of America shows that DTF prints maintain their color vibrancy for over 50 wash cycles, significantly outperforming heat transfer vinyl and competing with the best screen printing results. This durability translates directly into customer satisfaction and repeat business.

No Color Limitations, Unlimited Creativity

Remember the days when complex designs meant higher costs and longer setup times? DTF has eliminated those barriers completely. You can print photorealistic images, intricate gradients, and unlimited color combinations without worrying about additional setup fees or minimum order quantities.

This freedom has sparked a creativity revolution in custom apparel. Small businesses and independent creators can now offer the same high-quality, complex designs that were once reserved for large-scale operations. The Digital Textile Printing Market Report indicates that this democratization of high-quality printing is driving a 15% annual growth in the custom apparel sector.

Cost-Effectiveness That Makes Sense

Let's be honest – profitability matters. DTF printing offers exceptional cost-effectiveness, especially for small to medium-sized orders. Unlike screen printing, which requires expensive setup costs and minimum quantities to be profitable, DTF can handle single-item orders cost-effectively.

For businesses looking to test new designs or offer personalized products, DTF eliminates the financial risk of large minimum orders. You can print exactly what you need, when you need it. This on-demand capability is perfect for entrepreneurs using services like our Build a Gang Sheet option to maximize efficiency and minimize waste.

Speed and Efficiency in Production

Time is money, and DTF delivers on both fronts. The streamlined workflow – from design to finished product – is significantly faster than traditional methods. Once you have your DTF transfers ready, applying them takes just minutes with a heat press.

Modern DTF printers with automated features can produce hundreds of transfers per hour, making them ideal for both small custom orders and large production runs. The Society for Imaging Science and Technology reports that businesses using DTF technology have reduced their average production time by 40% compared to traditional methods.

Market Trends Supporting DTF Growth

The numbers don't lie – DTF is experiencing explosive growth. Market research indicates that the DTF printing market is expected to grow at a compound annual growth rate of 22% through 2028. This growth is driven by several factors:

- Increasing demand for personalized products

- Rise of e-commerce and print-on-demand businesses

- Growing small business and entrepreneur market

- Consumer preference for high-quality, durable prints

The COVID-19 pandemic accelerated the trend toward personalization and local production, creating perfect conditions for DTF technology adoption. Small businesses needed flexible, efficient printing solutions, and DTF delivered exactly what the market demanded.

Real-World Applications Driving Innovation

DTF's versatility extends far beyond basic t-shirt printing. We're seeing incredible innovation in applications like:

Athletic and Performance Wear: DTF works beautifully on moisture-wicking fabrics that challenge other printing methods

Fashion and High-End Apparel: The print quality rivals traditional methods while offering more design flexibility

Promotional Products: From caps to bags to signage, DTF opens new revenue streams

Small Batch and Custom Orders: Perfect for artists, influencers, and niche brands who need high quality without high minimums

These diverse applications showcase why DTF isn't just another printing method – it's a platform for business growth and creative expression.

Environmental Considerations

Sustainability is increasingly important to consumers and businesses alike. DTF printing generates less waste than screen printing (no screens to reclaim) and uses water-based inks that are more environmentally friendly than some traditional alternatives. The Environmental Protection Agency has noted that DTF technology produces fewer volatile organic compounds (VOCs) compared to solvent-based printing methods.

Looking Ahead: The Future is Here

The apparel printing industry is consolidating around technologies that offer the best combination of quality, versatility, speed, and cost-effectiveness. DTF checks all these boxes while continuously improving through technological advances.

New developments in DTF inks, films, and equipment are pushing the boundaries even further. We're seeing improvements in print resolution, increased transfer speeds, and enhanced durability that make DTF an even more attractive option for businesses of all sizes.

As consumer expectations continue to rise and personalization becomes the norm rather than the exception, DTF printing provides the foundation for meeting these demands profitably and efficiently.

Making the Switch to DTF

For businesses considering DTF technology, the question isn't whether you should make the switch, but how quickly you can implement it. At Abstract Printing Solutions, we've helped countless businesses transition to DTF printing, and the results speak for themselves – increased profitability, expanded product offerings, and happier customers.

The future of apparel printing is here, and it's DTF. Whether you're a small business looking to expand your capabilities or an established operation seeking competitive advantages, DTF technology offers the tools you need to thrive in tomorrow's market.

Ready to explore what DTF can do for your business? Check out our products and services or contact us to learn more about integrating DTF technology into your operation. The future is bright – and it's printed with DTF.